In this guide, you’ll discover the five upgrades that deliver the greatest return on safety, productivity, and profit.

The business case for safety is clear; OSHA reports that for every $1 invested in injury prevention, companies see a return of $2 or more. Here are the upgrades that make it happen, plus practical checklists for each one.

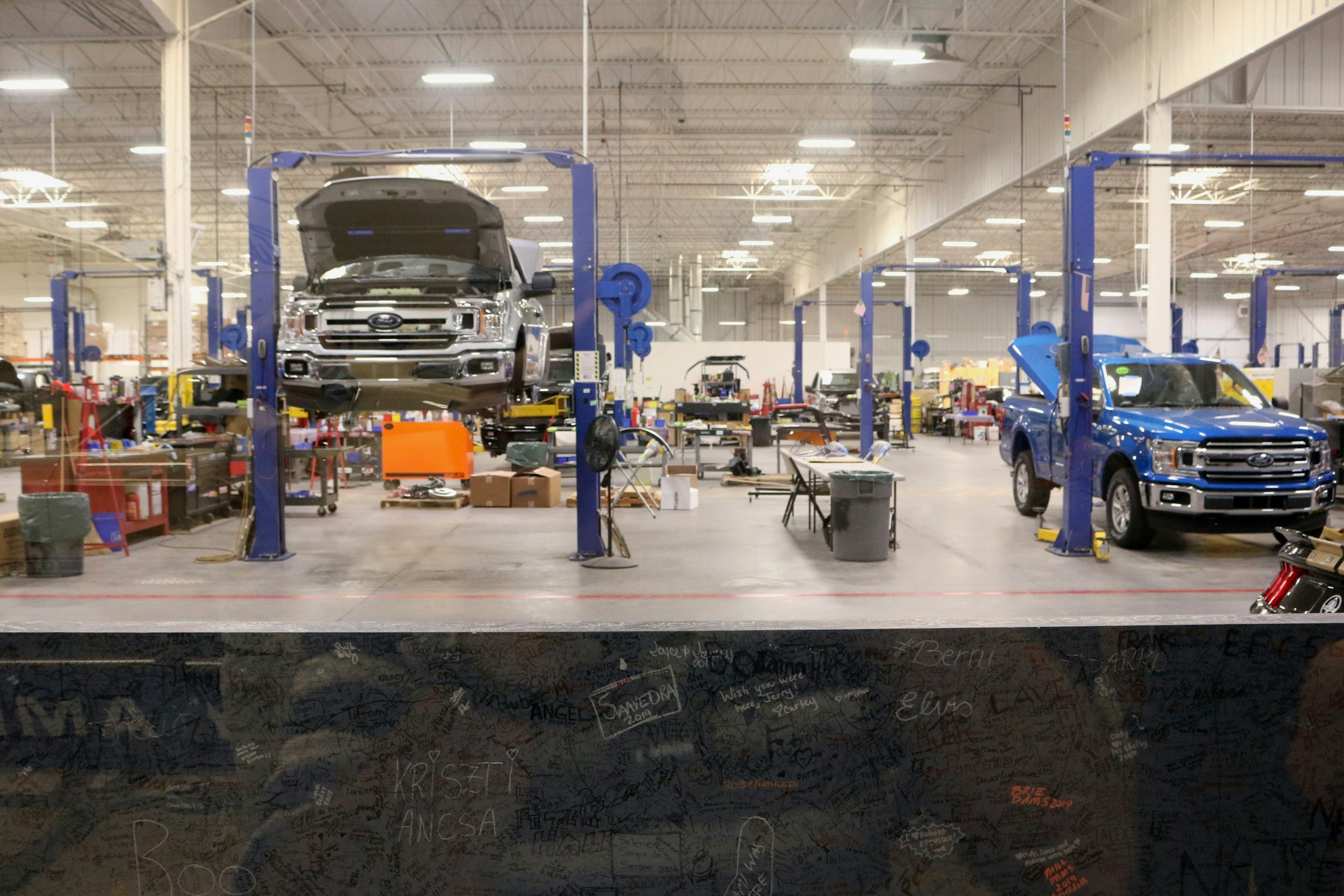

Upgrade #1: High-Quality Automotive Lifts & Stands

Choosing the right lift is fundamental to shop efficiency and safety. Two-post lifts are space-savers that maximize under-car access, making them ideal for general repair bays. Four-post designs provide a stable platform for wheel-alignment work and are excellent for long-term vehicle storage.

Safety should be the top priority. Always look for the Automotive Lift Institute (ALI) gold label. Certified models undergo rigorous testing that non-certified imports often skip, ensuring peace of mind for you and your technicians.

The productivity gains are significant, as swapping floor jacks for a certified two-post lift reduces vehicle setup time by 5 minutes per job.

For shops exploring certified mid-range options, the sturdy 2-post car lift from HeavyLift Direct balances ALI compliance with nationwide installation support. This simple change adds up to roughly 120 saved labor hours per bay over a year.

Budget-wise, expect to invest $3,000–$7,500 for mid-range two-post lifts and $6,000–$15,000 for four-post lifts. An implementation tip to boost efficiency further is to mount magnetic LED undercarriage lights on the lift arms to spot leaks faster.

| Key Insight: Swapping floor jacks for a certified two-post lift can save 5 minutes per job. Over a year, this small change adds up to approximately 120 saved labor hours per bay. |

Implementation Checklist

- ☐ Verify ALI certification on any considered model.

- ☐ Measure ceiling height and concrete thickness to ensure compatibility.

- ☐ Plan arm-reach zones to avoid accidental door dings on customer vehicles.

- ☐ Schedule annual professional load testing for compliance and safety.

Upgrade #2: Gas Detection & Exhaust Extraction Systems

Invisible gases pose a serious threat in any workshop. OSHA caps carbon monoxide (CO) exposure at 50 parts per million (ppm) over 8 hours, but a modern engine can hit 700 ppm at a cold idle. Prolonged low-level exposure leads to headaches, judgment errors, and long-term health risks.

Active extraction systems range from ducted fans for high-volume shops to retractable overhead hose reels for mixed-use bays.

A reliable multi-gas detector from PK Safety offers features like four-gas sensing and U.S. factory calibration. These systems are critical for pushing alerts to supervisors’ phones before dangerous thresholds are breached.

The return on investment comes from fewer sick days, reduced staff-comp claims, and potentially lower insurance premiums, often resulting in a 12–18 month payback period. To maximize effectiveness, sync detector data to your maintenance software to create automatic work orders for calibrations, removing human error from the safety loop.

| Important: A modern engine can produce 700 ppm of Carbon Monoxide at idle—14 times the OSHA 8-hour exposure limit. Proper gas detection is a non-negotiable safety requirement for protecting technicians. |

Compliance Checklist

- ☐ Map shop airflow and vehicle positioning to identify optimal detector locations.

- ☐ Verify the sensor life span of detectors before purchasing.

- ☐ Train all staff on alarm levels and designated evacuation routes.

- ☐ Log calibration certificates for regulatory compliance.

Upgrade #3: Advanced Diagnostic Equipment

In today’s complex vehicles, accurate diagnostics are non-negotiable. The essential toolkit includes an OBD-II scan tool, a digital oscilloscope, and a battery conductance tester. Emerging must-haves are ADAS calibration rigs and EV insulation testers to service the growing high-tech market.

The right tools dramatically boost productivity by trimming complex fault-finding time by 40 percent, saving nearly an hour of labor per diagnostic job.

One independent shop cut its average drivability diagnostic time from 2.5 hours to just 1.3 hours after adopting a combined scope-scanner workflow. This translated to a $110 per-job labor gain at their posted rate.

Remember that tool ROI depends on technician competency. Allocate 8–12 hours of paid training per tech, often available through e-learning modules bundled with the equipment. A great implementation tip is to create a “known-good” waveform library on a shared server for faster fault isolation.

| Pro Tip: The ROI of advanced diagnostic tools is directly tied to technician competency. Always budget for 8-12 hours of paid training to ensure the equipment’s powerful features are fully utilized for faster, accurate fault-finding. |

Implementation Checklist

- Evaluate current diagnostic coverage gaps (ADAS, EV, Euro makes).

- Budget for yearly software subscriptions to keep tools current.

- Designate a diagnostic champion in the shop to mentor other technicians.

- Track first-time-fix metrics monthly to measure improvement.

Upgrade #4: Garage Management Software Solutions

Efficiently managing workflow is key to profitability. Modern garage management software provides a backbone of control through digital job cards, integrated parts lookup, and key performance indicator (KPI) dashboards. Cloud-based platforms are popular for their minimal IT overhead and automatic updates.

Top-tier software integrates seamlessly with other business functions. Supplier ordering APIs can reduce parts-lookup time by 17%, and accounting exports push daily invoices straight into platforms like QuickBooks. Many programs also include real-time bay-loading views so service managers can balance workloads at a glance.

The most important KPIs to track are first-time-fix rate, average invoice value, and technician efficiency. Industry-leading shops consistently hit an 85% or higher first-time-fix rate and over 115% technician efficiency. Launch new software in phases to avoid overwhelming your team, starting with job cards and scheduling.

| Key Insight: Top-performing shops use management software to track KPIs, consistently achieving an 85%+ first-time-fix rate and over 115% technician efficiency. What gets measured gets managed—and improves your bottom line. |

Implementation Checklist

- Map your existing paper or digital workflows before choosing a system.

- Clean your parts inventory data thoroughly before importing it.

- Configure user permissions based on roles (technician, service advisor, manager).

- Book refresher training sessions every quarter to maximize feature usage.

Upgrade #5: Energy-Efficient Lighting & Equipment

Reducing overheads is a direct path to higher profits. Swapping old fluorescent tubes for modern LED high-bays is a simple but powerful upgrade. An 18,000-lumen LED high-bay draws about 150W versus a fluorescent’s 320W, a 53% energy saving.

Efficiency gains extend beyond lighting. Variable-speed air compressors match airflow to demand, slashing electricity consumption during idle cycles. Most garages recoup LED retrofit costs in just 6-12 months, especially after factoring in local utility rebates.

There’s a quality benefit, too. Improved visibility helps reduce comebacks. One insurer recorded a 7% drop in post-service claims after its network of shops upgraded their lighting, proving that a well-lit workspace is a more accurate one.

| Pro Tip: Beyond energy savings, upgrading to high-quality LED lighting can directly improve work accuracy. One insurer noted a 7% drop in post-service claims for shops with better lighting, reducing costly comebacks. |

Implementation Checklist

- Research and claim all available local utility rebates for retrofits.

- Specify lighting with a Color Rendering Index (CRI) of over 80 for color-critical work.

- Add emergency-battery modules to fixtures in exit routes for safety.

- Schedule quarterly lux-level checks to ensure consistent light quality.

Your Next Steps

Upgrading your garage doesn’t have to be an all-or-nothing leap. Start with safety-critical items like certified lifts and gas detection, then move to productivity multipliers like advanced diagnostics.

By strategically investing in these areas, you can create a safer, more productive, and more profitable workshop.

Article Last Updated: November 21, 2025.