It is a reliability- and precision-based industry where one defect or even a minor delay can be costly. With supply chains stretching across continents throughout the world, obtaining safe and efficient transport for sensitive commodities has been most imperative. In a highly competitive auto industry nowadays where competition is stiff, logistical chains must be efficient to provide quality commodities. Specialized solutions, such as refrigerated shipping containers for rent, have become indispensable for handling sensitive automotive parts. These containers are not just about keeping goods cold, they help preserve product integrity, reduce waste, and ensure that manufacturers, distributors, and customers receive parts in optimal condition.

Why Automotive Parts Require Controlled Environments

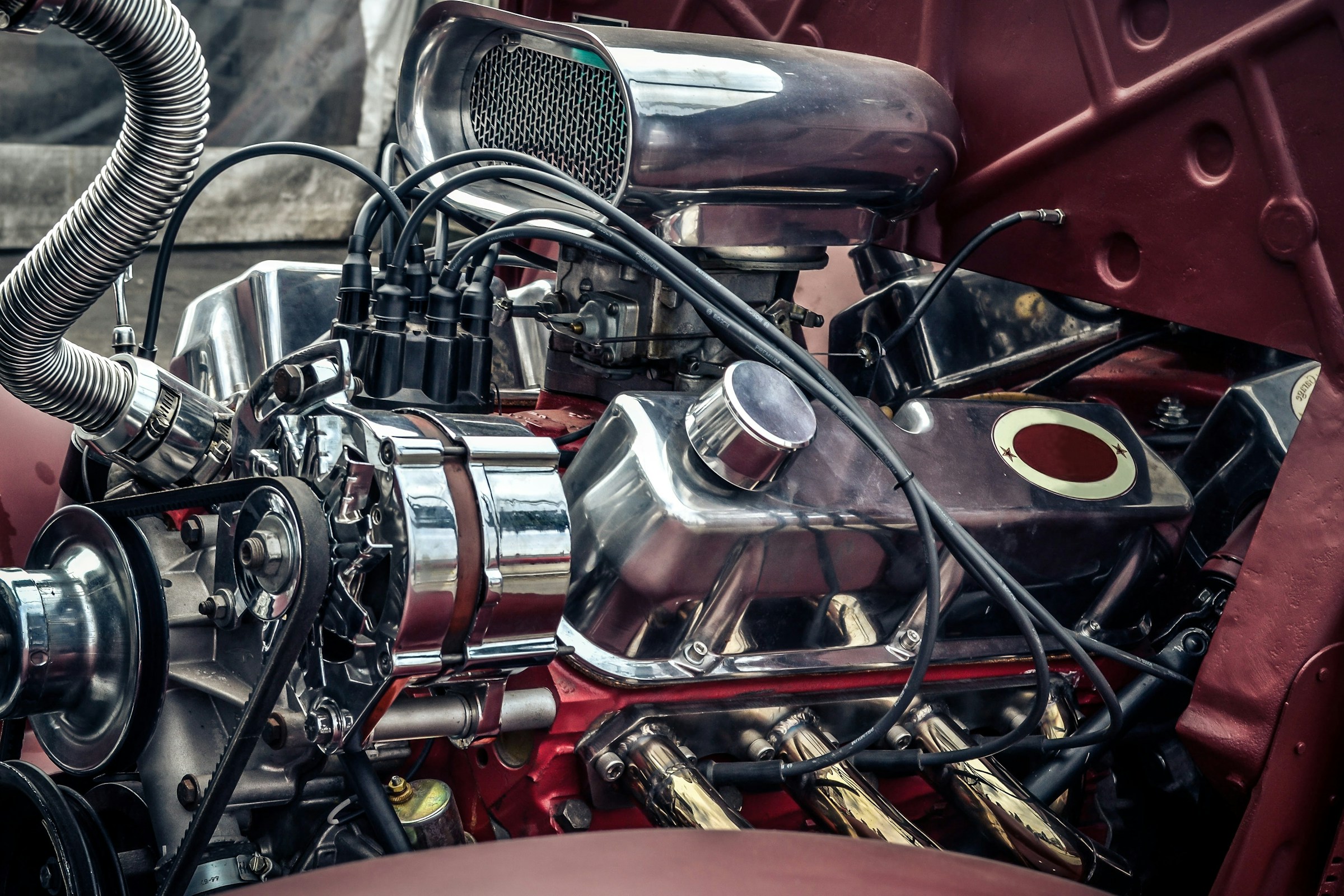

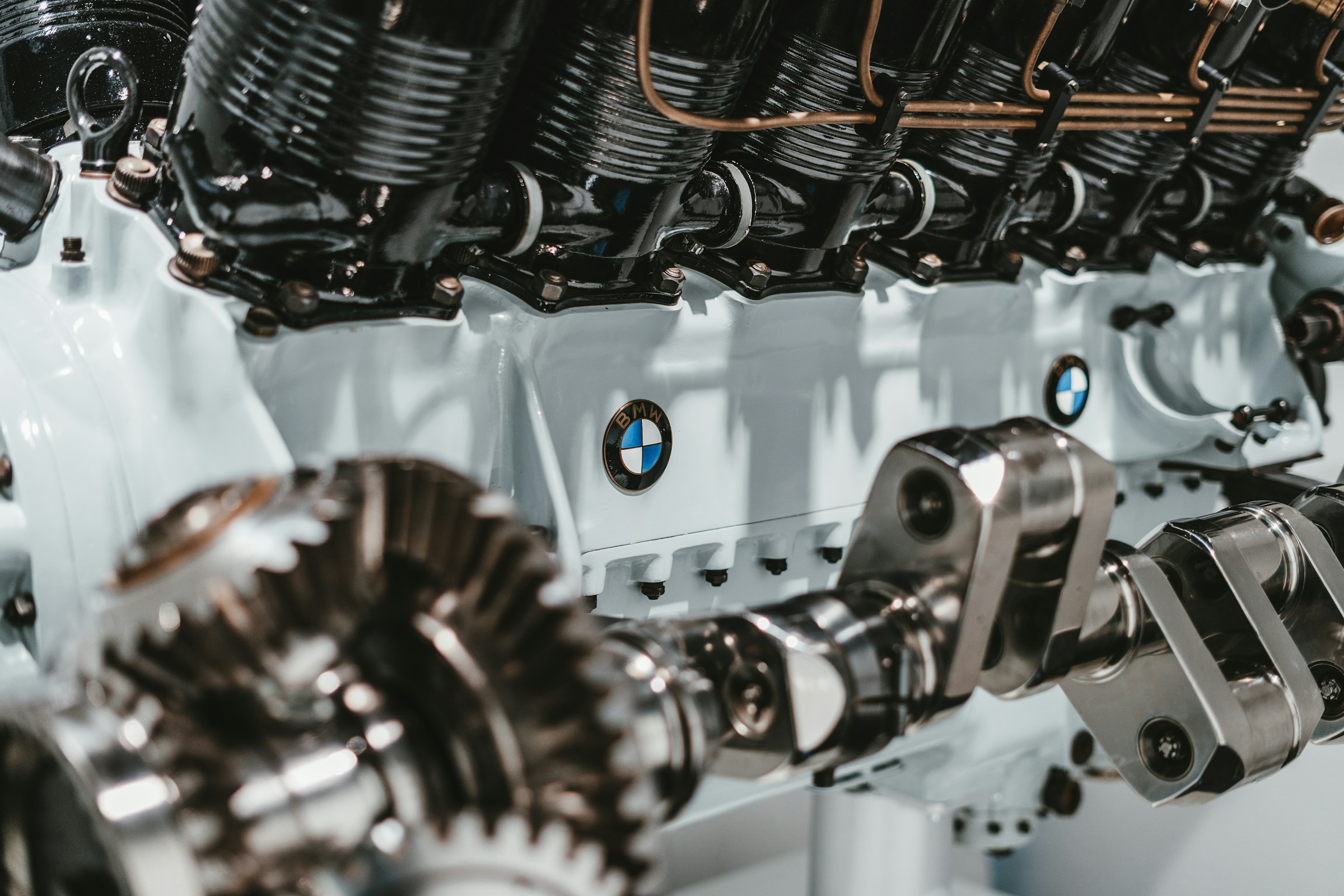

Auto parts have never been more high-tech than they are today, with most being made with highly-specialized materials responsive to changing temperatures or too much humidity. Rubber seals, adhesives, electronics, even some types of lubrication can degrade if they’re stored or transported under adverse conditions. Insulated refrigerated transport containers provide such parts with the constancy they need to withstand storage to shipment.

For instance, rubber seals and gaskets could become brittle or stiff if they’re kept in too hot or dry a place. On the other hand, electronic sensors or sensitive modules could fail if they’re subjected to an excessive amount of humidity. To avoid costly damage and retain parts within manufacturer tolerances, specific humidity and temperature levels should be maintained.

Benefits of Refrigerated Containers in Automotive Logistics

1. Temperature Control

Refrigerator containers allow operators to set and retain specific temperatures, often within close ranges. Such is necessary to preserve adhesives, paints, and polymers within selected temperature ranges to avoid chemical breakdown.

2. Humidity Regulation

Moisture is one of the biggest enemies to auto parts. Metal parts decay and electronics fail because of improper humidity control. Refrigerated containers escape such dangers by providing uniform humidity control.

3. Mobility and Flexibility

In contrast to cold storage warehouses that are bolt-down, refrigerated transport containers can be located wherever supply is most demanded near production centers, assemblage plants, or distribution centers. Being transportable enables their flexibility to respond to changing supply chain volumes.

4. Cost Efficiency

Refrigerated storage investment is advantageous to companies financially in the long run through reduced spoilage, lower warranty claims, and lower costs for replacement. Container leasing contributes additional financial flexibility to companies with intermittent or one-time projects.

Automotive Supply Chains and Environmental Challenges

Global auto supply chains involve very intricate networks where auto parts go across international borders. On long journeys, parts experience various climates from humid tropics to subzero temperatures. Without efficient climate controls, vulnerable products undergo damage during their journey to auto assembly lines.

For example, electronic units (ECUs) should be transported under constant conditions to prevent condensation that is capable of destroying circuits. Refrigerated containers prevent such an issue because they preserve a constant environment throughout transport.

Additionally, with auto production shifting more towards electric vehicles (EVs), highly sensitive components including lithium-ion batteries and temper-sensitive adhesives necessitate stricter transport and storage solutions. Refrigerated containers are used to meet such shifting demands.

Integration With Just-in-Time Manufacturing

Just-in-time (JIT) practices prevail throughout the automotive supply chain. Car parts must come just in time to be utilized at a factory with a minimum amount stored onsite. Anything lost or behind can grind an entire production lineup to a halt.

Refrigerated containers make possible JIT production with the guarantee that critical parts remain intact until they’re required at a particular time. Such a guarantee results in smoother operations with reduced interruptions and overall streamlined production lines.

Supporting Sustainability Goals

Many auto manufacturers are pushed to meet sustainability objectives alongside carbon-reduction goals. Refrigerated ship containers can contribute to such projects by:

- Minimizing Waste: Less part damage results in fewer parts scrapped or re-manufactured with consequent reduction in overall environmental impacts.

- Energy Efficiency: Latest refrigerated containers deploy energy-saving technologies to lower theircarbon footprint compared to older cooling systems.

- Efficient Transport: Ship containers can be included in multimodal transport chains (truck, rail, sea), with reduced redundant handling and packaging.

It aligns with general industry trends towards green supply chains and responsible management of resources.

Real-World Applications in the Automotive Sector

- Electronics and Sensors. Sophisticated electronics allow modern cars to operate for comfort, effectiveness, and protection. These delicate parts require storage with absolute precision to avoid breakdown.

- Tires and Rubber Products. Rubber products deteriorate with heat & UV radiation. Refrigerated containers preserve shelf life & flexibility.

- Paints, Coatings, and Adhesives. Temperature-sensitive commodities like paints and adhesives must be stored within close tolerances to be effective. When they are compromised, they can cause assembly defects in vehicles.

- EV Batteries and High-Tech Materials. As electric transport becomes more widespread, so does the value placed on exacting treatment of EV components. Batteries and high-tech composites often require steady, cool conditions along the way to storage.

The Future of Refrigerated Containers in Automotive Logistics

As the market expands, refrigerated containers will increasingly be a critical component. Things to watch for include:

- Increased EV production requiring stricter treatment of warm-sensitive parts. Supply chains went global with components transported through various climate zones.

- Technological advancements in containers such as remote monitoring as well as smart IoT sensors to facilitate real-time temperature and humidity monitoring.

These trends point to refrigerated containers remaining a core part of automotive supply chains for years to come.

Today’s automotive supply chain is a complex system requiring precision, dependability, and flexibility. Refrigerator ship containers have proven to be a key part of that system to afford sensitive parts protection, enable just-in-time shipment, complement sustainable goals, and be custom-designed to manufacturers’ and distributors’ respective needs.

Through the integration of refrigerated solutions with logistical plans, businesses protect product quality, minimize expenditure, and maximize operational effectiveness. For businesses seeking reliable storage and transport solutions, exploring options for cold storage containers https://midstatecontainers.com/collections/refrigerated-containers is a practical and forward-thinking step. Ultimately, investing in refrigerated containers is not just about temperature it’s about safeguarding an entire supply chain. Companies that adopt these solutions position themselves to stay competitive, resilient, and future-ready in an industry that evolves faster every year. As automotive technology advances, the importance of reliable cold storage will only continue to grow.

Article Last Updated: September 22, 2025.